“Eventually every company will have autonomy, I think, but not every company will be great at manufacturing [batteries]. Tesla will be absolutely head and shoulders above anyone else in manufacturing -- that is our goal.”

Tesla CEO Elon Musk has announced ambitious plans to pursue independent battery production. This includes acquiring the same scale of battery production facilities that LG Chem currently possesses within the next two years, and reducing battery unit prices by half within three years. The extraordinary content has drawn mixed responses from the industry.

Hastening EV timeline by five years

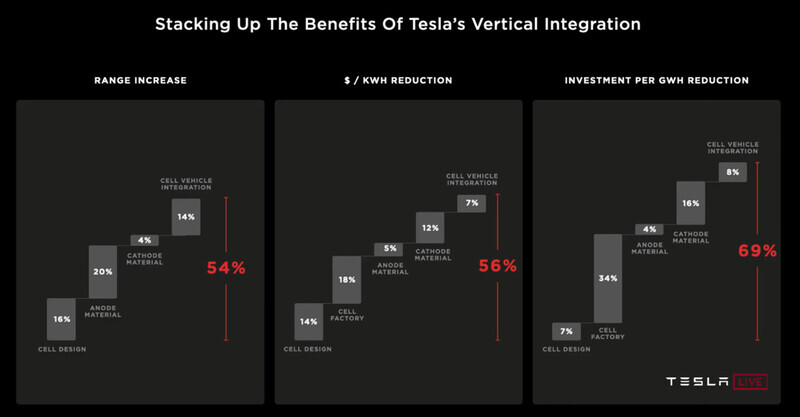

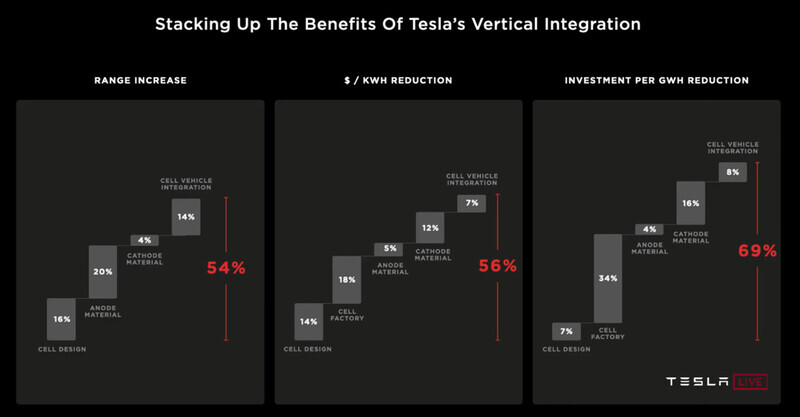

Tesla made its battery cell production plans official at a “Battery Day” event staged in front of its California headquarters on Sept. 22. The company announced that it had recently used its tabless cell design to produce a “4680” cylindrical battery cell with five times higher volume at its pilot facilities, with plans for mass production within one to two years. Musk has drawn particular attention with his emphasis on the number “56.” His claim is that once target levels are achieved with the technology currently being developed by Tesla in five areas -- including dry electrode coating and silicon anode materials -- battery pack costs will be reduced by 56%.

Musk said, “[I]t will take us probably a year to 18 months to start realizing these [technological] advantages, and to fully realize the advantages probably it’s about three years or thereabouts.” His plan to have an electric vehicle (EV) that costs US$25,000 on the market by 2023 is around five years ahead of industry predictions. According to a report by BloombergNEF, a lithium ion battery pack cost US$156 per kilowatt-hour last year. Bloomberg predicted that price would fall to US$94 by 2024 and to US$62 by 2030. If the “56% reduction within three years” from Tesla’s plans is applied, that US$156 cost would plunge all the way to US$69 as early as 2023 -- putting it far ahead of schedule in passing the US$100 mark where EVs are seen as becoming as affordable as internal combustion engine-based vehicles at the same level.

Plans to produce 100GWh by 2022

Tesla’s announcement also surpassed expectations in terms of scale. Musk announced plans to independently produce battery cells at the 100 gigawatt hour (GWh) scale by 2022 and the 3 terawatt hour (TWh) scale by 2030. LG Chem, which has the biggest production scale of any current battery company, is predicted to achieve annual production of 100GWh by the end of this year -- enough for 1-1.5 million EVs. That total is set to rise to around 30 million EVs’ worth by 2030. In contrast, Tesla is currently selling upwards of 400,000 EVs annually, with an ultimate target of 20 million.

Under the current plan, Tesla’s battery production volume is likely to overtake its EV sales. This explains why analysts have been interpreting Tesla’s message as a renewed emphasis on its identity as an “energy company.” Explaining his reasons for pursuing large-scale battery production that day, Musk said that transitioning the world to sustainable energy would require “10TWh for transportation [including EVs], 10TWh hours for the grid.”

Industry assessments were mixed. While Musk emphasized numerical targets that day with a “54% increase” in driving distances and “56% reduction” in battery pack prices, he did not offer reference points. A South Korean battery industry source said, “It costs about 10 trillion won [US$8.54 billion] to establish 100GWh’ worth of battery production facilities. It’s not clear whether that’s achievable within two years.”

A number of observers took the opposite view. In a report, Mirae Asset Daewoo analyst Park Yun-ju wrote, “As this direction involves boosting productivity in the existing battery process rather than presenting new battery technology, it appears largely feasible.”

Park also said that other companies are “expected to pursue similar technology development.”

By Lee Jae-yeon, staff reporter

Please direct comments or questions to [english@hani.co.kr]